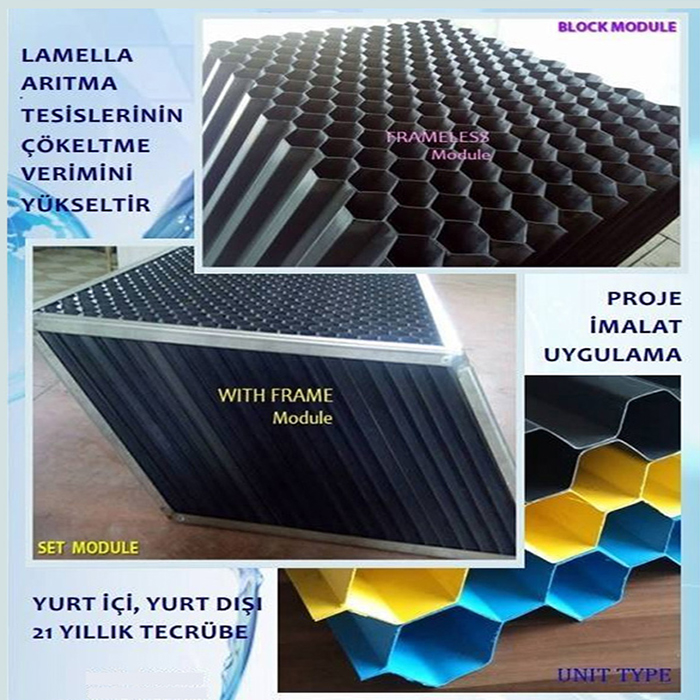

Tube Settler Application Types

Tube settler Lamellas used in industrial water treatment systems are manufactured in four basic categories based on their structural features:

Structural Feature: Consists of a single-piece trapezoidal-section lamella sheet.

Production Flexibility:

Custom manufacturing according to project requirements.

Production capacity in desired widths (500-1120 mm) and lengths (600-300 mm).

Standard thickness: 1.0-1.5 mm

Material Options:

PVC and PP (Polypropylene)

UV-treated, Slippery, hygienic, and bacteria-free, certified production suitable for drinking water is the most important advantage of plate-type lamellas. However, the need for specialized machinery and the difficulty of on-site fabrication are their most significant disadvantages.

Sheet Type Tube Settler Price

Assembly Structure:

It consists of two symmetrical (1-Plate Type) lamella plates joined together by ultrasonic welding.

The advantage of unit-type lamellas is that they are more economical, eliminating the need for a frame for smaller tanks; if a frame is needed, the customer can fabricate it themselves.

Unit Type Tube Settler Price

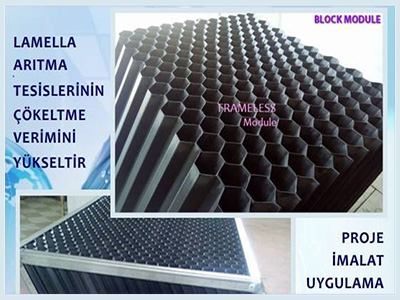

It has a modular structure and is obtained by gradually adding 4-20 lamella plates.

No frame is required. They are placed side by side or back to back directly in the pool/tank.

The most important advantage of block type lamella is its cost-effectiveness.

Block Type Tube Settler Price

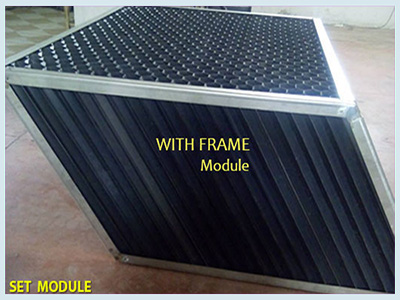

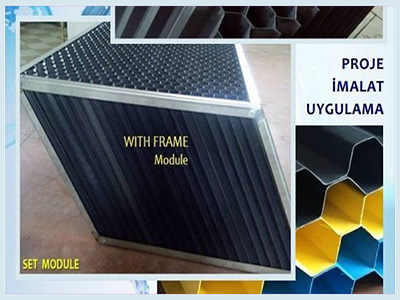

Its structure consists of a protective outer cage and a Unit type lamella inside.

It can be manufactured to any desired size to suit every project.

The frame is made of 304 quality stainless steel.

The advantages of framed-type lamellas are their durability, ease of maintenance and service, and their aesthetic appeal, adding value to projects.

Framed Type Tube Settler Price

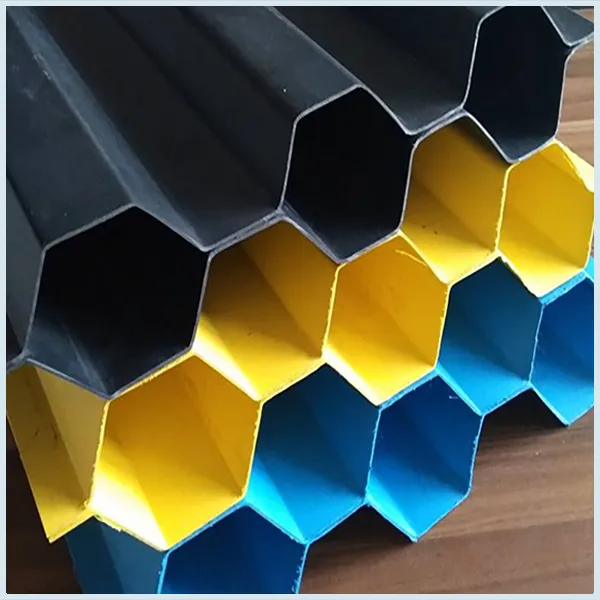

Unit Type Lamella

It consists of two panels. It is formed by welding the two panels symmetrically together. It can be manufactured in any desired size by splicing or cutting. It is the first building block in the formation of the honeycomb surface.

Splicing: It is done at multiple points with an ultrasonic welding machine.

Cutting: The edges are cut with guillotine. The ends are cut with hydraulic press blades at the desired angle of 55-60 degrees. Unit type lamellas, whose ends are not cut at an angle, can easily break when the ends touch the ground below.

The Importance of Water Purification with Tube settler Systems

Water is the fundamental resource of life, and access to clean water is critical for a sustainable future. Today, many technologies have been developed for wastewater treatment and clean water production. These include:

A

Tube settler Lamella is a sedimentation system consisting of inclined plates. These plates enable suspended solids (sediment, sludge, particles) in water to settle more quickly and efficiently.

Tube settler Lamella systems for wastewater treatment offer a significant advantage, especially in the treatment of high-flow wastewater. Because they provide high efficiency in a small space, they take up less space than traditional sedimentation tanks.

Tube settler Lamella systems for clean water treatment are frequently used in drinking water treatment plants. Particles that cause turbidity in the water settle between

Tube settler Lamella plates, helping to clarify the water. These systems, also called clarifier

Tube settler Lamellas, provide preliminary treatment before the water is transferred to the filtration stage.

One of the greatest advantages of

Tube settler Lamella systems is their energy efficiency and low operating costs. Furthermore, their modular structure allows them to be easily adapted to meet different treatment needs.

In conclusion,

Tube settler Lamella technology is an indispensable solution for the protection of water resources and sustainable water management. In the face of increasing water pollution problems, expanding the use of these systems will increase access to clean water and contribute to maintaining environmental balance.

Tube settler Lamella Technology: Efficiency and Sustainability in Water Treatment

Today's growing population, industrialization, and climate change place significant pressure on clean water resources. Therefore, water treatment technologies are becoming increasingly important.

Tube settler Lamella systems stand out as technologies that provide high efficiency, space savings, and economical solutions for water and wastewater treatment.

The Importance of Water Treatment with Tube settler Lamella Systems

Water is the fundamental resource of life, and access to clean water is critical for a sustainable future. Today, many technologies have been developed for wastewater treatment and clean water production.

Tube settler Lamella systems are one of these. These systems, with their variations such as clarifier

Tube settler Lamella and purifier

Tube settler Lamella, are widely used in both industrial and municipal treatment plants.

A

Tube settler Lamella is a sedimentation system consisting of inclined plates arranged parallel to each other. In this system, water slowly passes between the plates, while suspended solids (sediment, sludge, colloidal particles) settle by gravity. The inclined design of the plates allows the settled solids to collect at the bottom, and the cleaned water exits at the top.

These systems, also known as clarifier

Tube settler Lamellas, provide rapid and effective sedimentation, especially in high-flow water. They take up much less space and offer higher efficiency compared to traditional sedimentation tanks.

Tube settler Lamella for Wastewater Treatment

Tube settler Lamella systems are used in the physical treatment phase of industrial and domestic wastewater treatment, particularly in the treatment of high-solid content wastewater. They are effective in the pretreatment of wastewaters. They are widely preferred for the treatment of wastewater in the chemical, food, textile, and mining sectors.

Tube settler Lamella for Clean Water Treatment

Clarifying

Tube settler Lamella systems are used in drinking water treatment plants to remove turbidity from raw water. They clarify water by sedimenting suspended solids in rivers, lakes, and dams. This reduces the burden on filtration and disinfection stages.

Rainwater Treatment

Tube settler Lamella systems are used to remove pollutants carried by rainwater, especially in urban areas. They prevent environmental pollution by sedimenting sediment, oil, and other contaminants in surface runoff.

Advantages of

Tube settler Lamella Systems

High Efficiency: Thanks to the plate structure, sedimentation rate increases, allowing more water to be treated in a shorter time.

Space Savings: Requires significantly less space than traditional sedimentation tanks, a significant advantage especially for urban treatment plants.

Low Operating Costs: Energy consumption is low, and maintenance requirements are minimal.

Modular Design: Can be expanded to accommodate capacity increases and easily adapted to different flow rates.

Conclusion

Tube settler Lamella technology is an environmentally friendly and economical system that offers modern solutions for water and wastewater treatment. It has a wide range of applications, from industry to municipalities, with applications such as clarifier

Tube settler Lamellas and purifiers. The widespread adoption of this technology for the protection of water resources and sustainable water management is crucial for providing clean and reliable water for future generations.

The increasing global population and the rise of water stress